Products

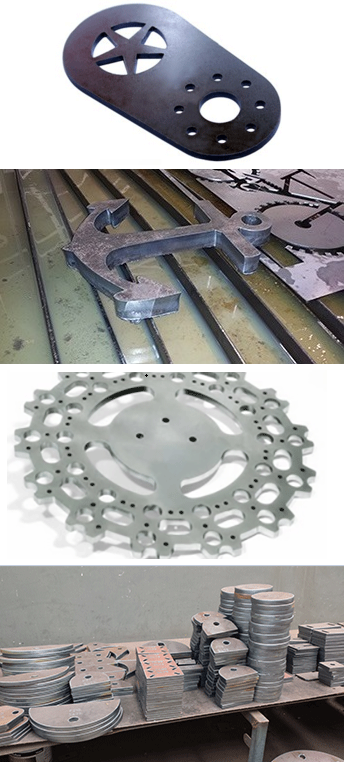

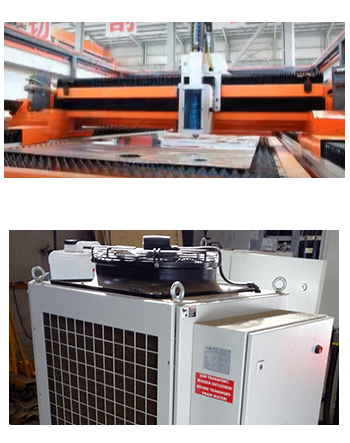

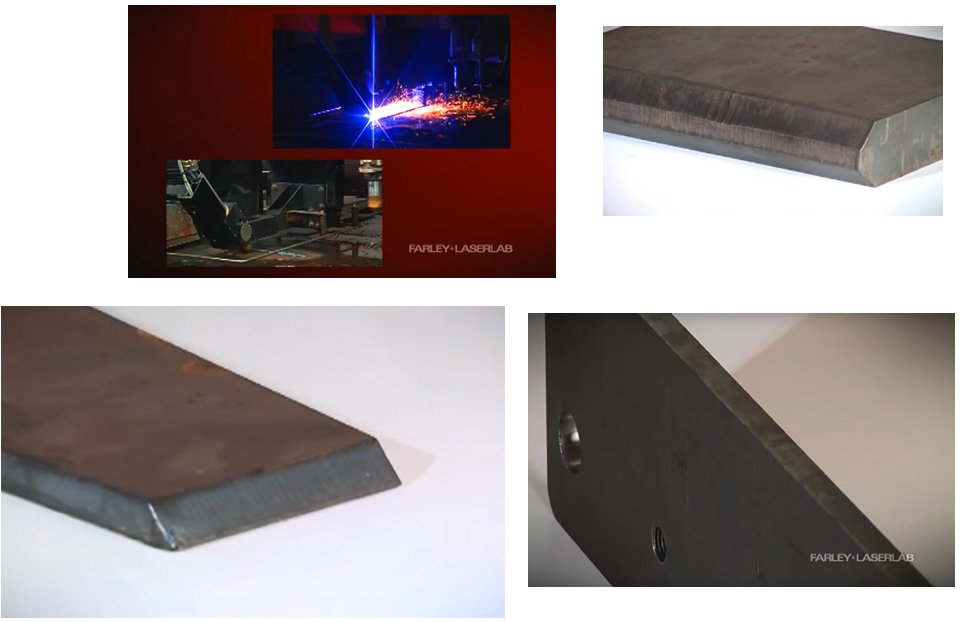

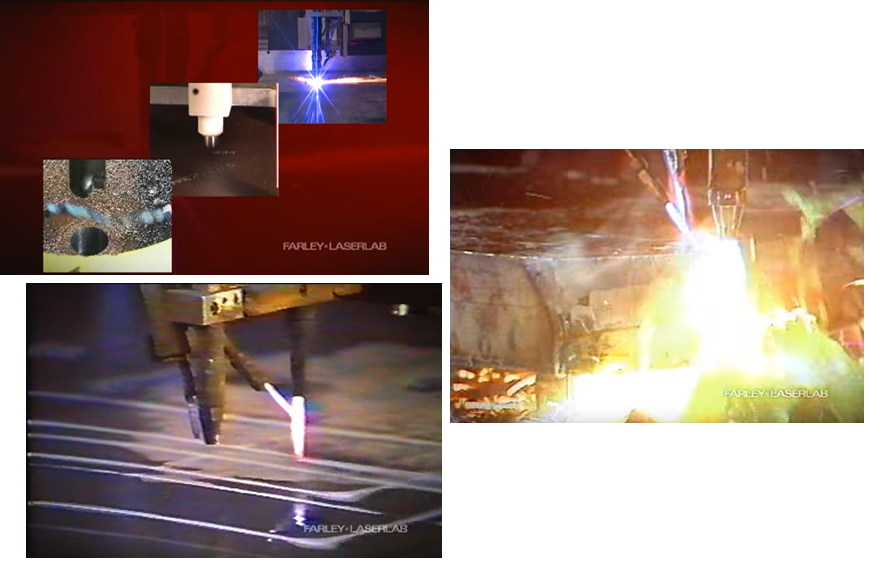

High Definition CNC Plasma Cut, Oxygen Cut, Laser Cut, WaterJet Cut, CNC Drilling & Milling Machines

As Lynx Global; in a very wide geography, within the network of the strong and dynamic relationships that we have established in long years and have been constantly developing in more than a hundred countries on five continents and by operating in many industrial sectors with a rich variety of products and services; we, together with our contracted direct manufacturer, qualified supplier partners; always do our best on the basis of “win + win + win” cooperation philosophy with all our personnel, machinery, equipment and facility possibilities, knowledge, experience, vision, mind and heart to respond fully and accurately to countless expectations and needs of our all customers in various industrial sectors in all countries that allow us to provide cooperation.

In this context, as Lynx Global & Its Supplier Partners Group; in the form of a body of expert competents equipped with advanced facilities where we work together like a single organization in a complete discipline of integration and a solid, intertwined structure in our every single project and every operation of our projects without exception; here, we present to you transparently and elaborately; our knowledge, experience, vision and all kinds of physical and other equipments, abilities and competencies and the sum and all relevant details of them regarding all the possibilities and capabilities which we all have together as one in total in this product + service class.

We are, in this industrial segment, one of the world leaders in the fields of High Definition CNC Plasma Cutting, Oxy Cutting, Laser Cutting, WaterJet Cutting and CNC Drilling Machines. We have been manufacturing and supplying CNC laser & plasma cutting machines to the world industry for over 30 years. Today we have thousands of CNC profile machines installed in over 24 countries worldwide and now we have teams in five continents and in more than a dozen of countries with more opening in South America as well.

The cutting machines we provide are products attributed to years of customer collaboration, research and development which contributes to the ongoing success of our future projects. This is what makes our company a leader in laser & plasma cutting and drilling machine tool technology. We have produced the very best in cutting machines for the past 30 years and continue to develop new technologies for the future.

We have some of the best technicians and engineers in this field, service technicians and support engineers to help out our customers when in need. Our technicians & engineers are involved in the manufacturing, assembling, installing and commissioning of each machine that goes out to our customers, so; they know your machine better than anyone else and will be the best people to talk to when you are in need of a quick fix. So; if you get one of our machines; we ensure you contact a technician of our company to make sure your machine runs smoothly.

On top of this we have many more technicians to help us from around the world be it our team in China or the US but also from Hypertherm's technical team that will only help out official O.E.M channel partners and not resellers. Meaning you get the best service from our teams together any time you need it.

Also make sure when you are dealing with a machine of our company you deal with our techinicians for the best possible service, too many people in the past have tried to save a dollar by hiring people who have worked with our machines 15+ years ago and do not understand the changes in technology that have been made, and this all ends up costing you triple the amount that you thought you were saving, due to firstly others taking 2 - 3 times longer to finish the job and then us having to fix up the job afterwards.

Why our company together with Hypertherm provide a better service than our competitors:

1. Qualified engineers and technicians of our companies together who are involved in the manufacturing, assembling, installing & commissioning stages of each of our machines

2. Quick service times, they know all parts of our machines, so; problem solving is much quicker, no fumbling around working out how things work.

3. Our own engineering & drawings together - Every component of our machines has detailed technical drawings, part numbers and databases of related suppliers, which will again mean quick problem solving.

4. Our engineers together who have designed each component on our own machines, so; when you are in need of quick help and have capable employees then you just need to give our engineers a call for phone support, which is free to our account customers.

5. With our teams of qualified and educated technicians and engineers we are together significantly faster, so your 8 hour job that you will pay to get other companies 'who say' they can work on our machines can be completed in an hour with our technicians who are involved in the manufacturing phases of the related machines. So save yourself the time and the money and make sure you get one of our technicians to help you out with your need of service.

Here; We, Together Proudly Present Our CNC Laser Cutting Machines Selection

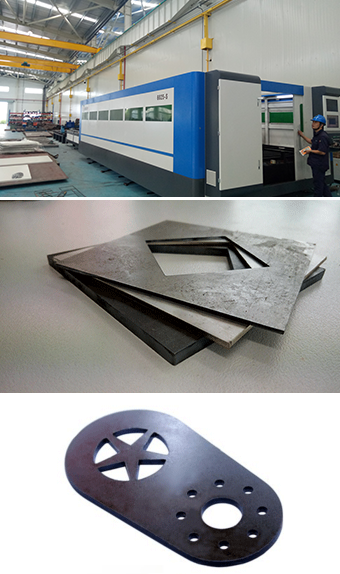

FIBER LASER CUTTING MACHINES:

EcoSHAPE FIBER LASER MACHINE

GF-X PLUS 6060 FIBER LASER MACHINE

GF PLUS FIBER LASER MACHINE

MARVEL FIBER LASER MACHINE

DF CONTOUR FIBER LASER MACHINE

Please proceed below for detailed information.

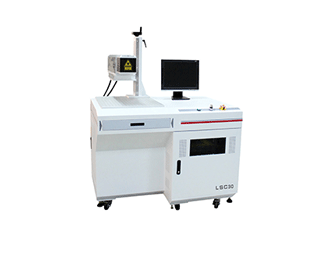

EcoSHAPE Fiber Laser Machine

Our EcoSHAPE CNC fiber laser cutting machine is a great low cost cnc fiber laser machine for small workshops and the HVAC Industry. Now with a budget price starting at a very competitive price level, it means anyone can now start achieving laser cut quality. The special price package includes the EcoSHAPE machine, Raycus 500W Fiber laser, Cutting Table 3m x 1.5m and our advanced CNC Controller.

Machine Details:

Our EcoSHAPE CNC laser cutting machine adopts gantry-motion structure, linear guide, screw drive, AC servo motor and drives and vacuum system(both sides) etc. The one-time processing area is 3m*1.5m. Not only that the equipment's design is advanced and reliable but also that all key components are from both national and international well-known brands.

4.5m x 2.3m x 1.5m (Machine)

5.0mm Mild Steel

1.6mm Aluminum

8.0mm Mild Steel

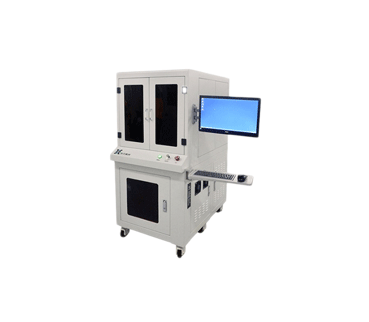

GF-X Plus Fiber Laser Machine

Our GF-X Plus CNC fiber laser cutting machine is the latest and greatest in low cost, low maintenance laser machines that we have together introduced to the global market. Now with an even more affordable price starting at a very competitive level; it means anyone can now start using the latest technologies for the business big and small. The special price package includes the GF-X Plus machine, External Cover (required for some countries), IPG 500W Fiber laser, Cutting Table 600mm x 600mm and the our advanced Cypcut CNC Controller.

5.0mm Mild Steel

8.0mm Mild Steel

GF Contour Fiber Laser Machine

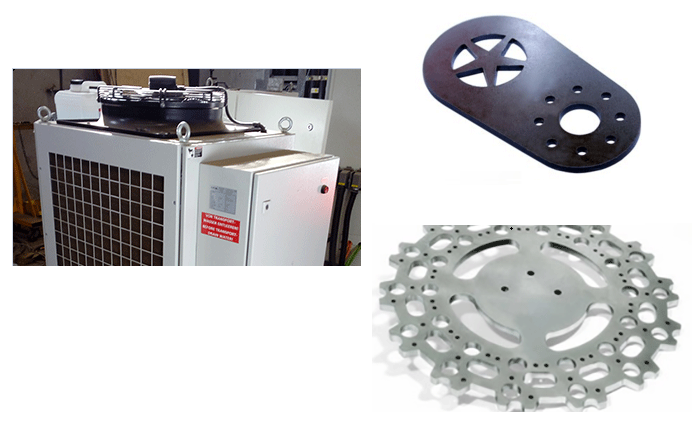

Our GF Plus CNC fiber laser cutting machine is the most affordable industrial low cost, low maintenance laser machines that we have together introduced to the global market. Now with an even more affordable price starting at a competitive level; it means anyone can now start using the latest technologies for the business big and small. The special price package includes the GF Plus machine, External Cover (required for some countries), our advanced 1000W Fiber laser, Water Chiller, Yaskawa Drives & Motors, CypCut CNC Controller, Cutting Table 3m x 1.5m and the WSX Auto Focus Laser Cutting Head.

4.5m x 2.3m x 1.5m (Machine)

5.0mm Mild Steel

8.0mm Mild Steel

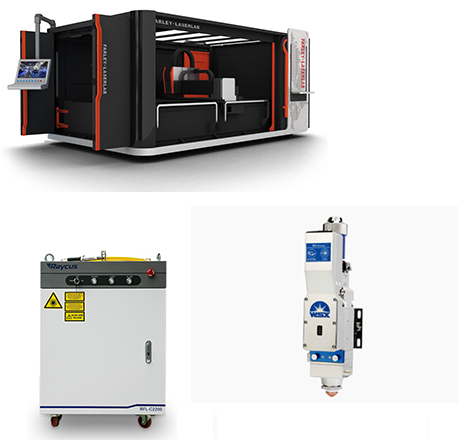

MARVEL Fiber Laser Cutting Machine

Our Marvel Fiber Laser Cutting Machine, is the latest machine in our range - now introducing our latest advanced ANCA CNC Controller, with again our together supporting national manufacturing and give you that piece of mind to get dual local support, rather than buying direct from China or having a German machine (That is made in China) that only one company can support and will charge you very high service fees.

Machine Details:

The Marvel Fiber laser cutting machine by us together adopts a gantry-motion structure, linear guide and screw drive, AC servo motor and drives, dual-side fume extraction system that delivers high performance laser cutting quality by equipping with a world leading RAYCUS-2200W fiber laser source. Not only it is highly recommended for carbon steel cutting, but also excellent for SS plate, aluminum alloy plate and copper plate cutting.

8.5m x 2.3m x 2.0m (Machine)

16.0mm Mild Steel

6.0mm Stainless Steel

20.0mm Mild Steel

10.0mm Stainless Steel

25.0mm Mild Steel

16.0mm Stainless Steel

DF Contour Fiber Laser Cutting Machine

Our DF Contour CNC fiber laser cutting machine is designed for heavy industrial fiber laser cutting, with a laser source up to IPG's 6kW Fiber Laser and a transfer table to give both speed and efficiency to give your business a step into the future. Now with an even more affordable price starting at a very competitive level; it means anyone can now start using the latest technologies for the business big and small. The special price package includes the DF Plus Machine, External Cover (required for some countries), IPG 2000W Fiber laser, IPG Water Chiller, Siemens Drives & Motors, Siemens CNC Controller, Cutting Table 3m x 1.5m, Transfer Table and the Precitec Laser Cutting Head.

Machine Details:

We together have designed and manufactured the latest fibre laser cutting machine to rival any C02 cutting machine on the market today. With its durable design the DF3015 utilizes a gantry structure with dual rack & pinion drives and AC servo motors providing you with a high precision, fast and reliable machine that will save on power bills.

Exclusive function of the DF3015:

Expert database, with material thickness, processing techniques,

speed matched with main parameters such as gas bars ion, air

pressure, capacity factor;

Jumping mode to enhance cutting effectiveness; Quick response

surface monitör;

Re-trace mode when job ignorance, operator is allowed return

obvious mode when missing job is checked;

High-speed responses laser power slope adjustment to ensure the

cutting quality of the corner point;

Laser piercing adjustable slope function to improve the piercing

quality;

Line / Circle complement and kerf compensate function;

Fly-piercing function for thin plates: non-stop cutting which

dramatically improve the cutting efficiency;

Automatic edge detecting function

(1.5m x 3.0m) 8.5m x 2.3m x 2.0m (Machine)

12.0mm Mild Steel

20.0mm Mild Steel

Here; We, Together Proudly Present Our CNC Laser Cutting Machines Selection

CO2 LASER CUTTING MACHINES:

PROFILE PLUS CO2 LASER MACHINE

DM CONTOUR CO2 LASER MACHINE

Please proceed below for detailed information.

Profile Plus CO2 Laser Cutting Machine

Our DF Contour CNC fiber laser cutting machine is designed for heavy industrial fiber laser cutting, with a laser source up to IPG's 6kW Fiber Laser and a transfer table to give both speed and efficiency to give your business a step into the future. Now with an even more affordable price starting at a very competitive level; it means anyone can now start using the latest technologies for the business big and small. The special price package includes the DF Plus machine, External Cover (required for Australia), IPG 2000W Fiber laser, IPG Water Chiller, Siemens Drives & Motors, Siemens CNC Controller, Cutting Table 3m x 1.5m, Transfer Table and the Precitec Laser Cutting Head.

Machine Details:

Our Profile Plus is the best value for money laser cutting system available on the market today. The Profile Plus is a reliable, flexible, profitable and affordable laser cutting system. The Profile Plus is a complete laser cutting system incorporating a 1.5m X 3m high speed transfer table to reduce down time caused by loading and unloading. The Profile Plus comes with a Hass cutting head and Precitec Height following system. The Profile Plus runs all Siemens servos and drives with a Siemens 840D controller and our advanced HMI. The Profile Plus comes with a choice of laser resonators including PRC and Rofin. The Profile Plus is the best value for money laser cutting machines available with 1000's installed worldwide.

20.0mm Mild Steel

10.0mm Stainless Steel

DM Contour CO2 Laser Cutting Machine

Our DM Contour CNC CO2 laser cutting machine is designed for heavy industrial laser cutting, with a laser source up to 6kW CO2 Laser and a transfer table to give both speed and efficiency to give your business a step into the future. Now with an even more affordable price starting at a very competitive level; it means anyone can now start using the latest technologies for the business big and small. The special price package includes the DM Contour machine, External Cover (required for Australia), Rofin DCO20 2000W CO2 laser, Laser Water Chiller, Siemens Drives & Motors, Siemens CNC Controller, Cutting Table 3m x 1.5m, Transfer Table and the Precitec Laser Cutting Head.

Machine Details:

The proven, reliable and affordable laser cutting system, with automatic transfer table and excellent accessibility. Our Contour DM provides Laser cutting at a repeatable high performance level, with gantry structure, cast Al beam and double side rack and pinion driving system, which supply the machines with high dynamic response speed and 1G acceleration to make sure the corner cutting quality.

Exceptional mechanical design, time proven worldwide supported Siemens 840D control system and German made speed reducer and matched skew gear moving structure are some of the many featured that allow for the machines' single axis maximum running speed up to 120m/min and max. combined speeds up to 165m/min while maintaining stability and precision. The Contour DM can process plate up to 2m (6') wide and 6m (12') long in one set up, and can be programmed to automatically transfer new material to the processing station via the fully automated transfer table.

20.0mm Mild Steel

10.0mm Stainless Steel

Here; We, Together Proudly Present Our CNC Laser Cutting Machines Selection

SPECIAL LASER CUTTING MACHINES:

LT CONTOUR PIPE LASER MACHINE

Please proceed below for detailed information.

LT Contour Pipe Cutting Machine

Our new LT9035 is a milestone advancement in new Fibre Laser cutting technology. Specifically designed for high volume cutting of tubes and pipes the LT 9035 provides far greater efficiency than normal laser systems when cutting pipes and tubular metals. New enhancements allow the LT9035 to position and move tubes and pipes mechanically (eliminating manual handling) to increase speed, precision and productivity.

Exclusive Functions of the 9035 Laser Pipe Cutting Machine:

Full automatic Feeding system – regular and rectangular pipes can be integrated into a fully automated feeding process, without human operation.

Advanced clamping system can self adjust focus according to material size, automatically adjusting clamping force, this ensures that the correct amount of clamping force is applied so that pipes do not get damaged.

Corner fast cutting system provides fast response to corners, greatly improving cutting efficiency. High efficiency unloading system – the LT9035 can be set to automatically unload finished work pieces, gently and safely in designated areas.

LT Contour 9035 Technical Data

Configurations

Length of Pipe 4000mm -8500mm

Remnant Pipe Length <250mm

Max Pipe Cutting Length 3500mm

Max Weight of Pipe 200kgs

Laser Type

2kw IPG Fibre Laser

Cutting Parameters

X axis stroke 8500mm

Y axis stroke 250mm

Z axis stroke 180mm

Rapid Positioning speed 100m/min

X, Y Axes Positioning Accuracy ±0.05mm

X, Y Axes Repeat Accuracy ±0.03mm

Control Siemens 840D + Our Advanced LaserSIM

CAM Software LANTEK CAD/CAM or Hypertherm PRONEST CAM

Here; We, Together Proudly Present Our Plasma Cutting, Drilling & Milling Machines Selection

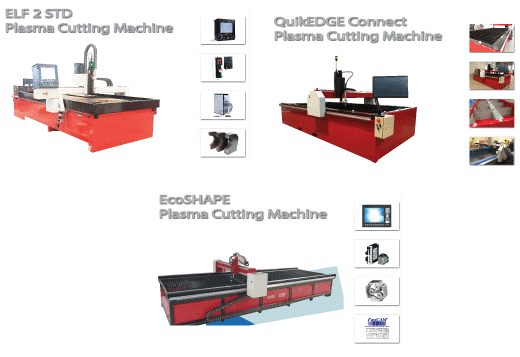

STANDARD DEFINITION PLASMA CUTTING MACHINES:

EcoSHAPE PLASMA MACHINE

QuikEDGE Connect PLASMA MACHINE

ELF 2 STD PLASMA MACHINE

Please proceed below for detailed information.

EcoSHAPE Table Plasma Machine

The EcoSHAPE CNC Table Plasma Cutting Machine introduces the optimum in low cost, high value machinery into the global market for companies looking into entering the CNC industry. The EcoSHAPE machine has been engineered by our teams together to suit the demands in our industry for low cost plasma cutting while still providing Hypertherm’s Standard of Air Plasma Cutting. Designed to provide companies in the need for a quality light / medium duty plasma machine at a low cost. We together will provide all the support required on the EcoSHAPE Table Machine, so through us; you can deal with experts in the industry with a dedicated service team for easy operations.

EcoSHAPE Plasma Advantages:

The EcoSHAPE machine is designed to give you an edge over your

competition such as:

Low Cost Affordable Machine

High Quality Air Plasma Cutting up to Hypertherm PowerMax 125

(Comparable to more expensive machine)

High Precision Cutting Quality (Achieved with AC Servo Motors and

Planetary Gearboxes)

ARM Based CNC Controller for easy operation

Automatic Torch Height Controller for higher quality cutting

Industrial Plasma Table - Dry or Water Table Option (up to 25mm

Plate across the table)

Automatic CAM Software Nesting for easy operation

Our Reliable Installation, Service & Warranty (Less downtime

on your machine)

Our Qualified Spare Parts & Consumables (Less downtime on your

machine)

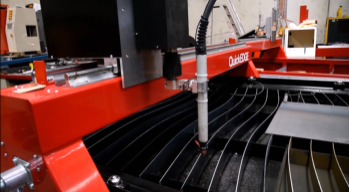

QuikEDGE Connect Plasma Machine

We are together introducing the latest in Hypertherm Technology at affordable pricing with our QuikEDGE Connect Plasma Cutting Machine. So; no need to get USA or UK made machines when you need a heavier duty processing center, plus; you get the latest technology from us together as Hypertherm Combined.

The QuikEDGE Connect Plasma machine is a great long term acquisition for any workshop to be utilized for in-house plasma cutting when they cannot wait for outside jobshops. With its ability to upgrade from Hypertherm's PowerMax Range to its latest HD Plasma Suite it offers you the flexibility that small machines need.

The QuikEDGE Connect Plasma Machine Includes:

Our advanced QuikEDGE Machine:

Dry Cutting Table with 750mm Zones (reduces fume extraction

requirements)

Cutting Area: 1.5m Width x 3.0m Length (upgradeable to 6.0m

Length

Hypertherm PowerMax Plasma Unit (upgradeable to HD Plasma)

Latest* Hypertherm Edge Connect CNC Controller - 19inch Touch

Screen

Hypertherm Pronest LTS CAM Software

4-Axis EtherCAT Drives & Motors

Our Advanced Auto Height Lifter EtherCAT Driven

Machine Speed up to 20m/min (actual speed not theoretical)

Our Together Factory Training Melbourne

Machine Dimensions (1.5m x 3.0 Cut Area) = 2.4m Width x 4.0m

LengtH

QuikEDGE Connect Machine Upgrades - Real money making upgrades:

CHS Pipe Cutting Option

CNC Spot Drilling up to 12mm Diameter MS

CNC Oxy Cutting Torch

CAMDUCT 2017 Machine Compatiable

Integrated HVAC Decoiler

Upgrade to Hypertherm HD Plasma Cutting

Upgrade to 6.0m Length Cutting

Industrial Fume Extraction Unit

Industrial Air Compressor, Dryer & Filter Package.

Benefits of QuikEDGE Machine Design:

Australian Made & Engineered (Experts of CNC Plasma Machinery

for 30+ Years)

Australian Steel & Fabrication (Supporting Australian

Industry)

Heavy Duty Design (10+ Year Machine Life)

Precision Motion System (Using High End Components for Quality

Motion)

Industrial & Low Maintenance (Low maintenance &

replacement of parts)

Hypertherm EDGE Connect Controller Benefits:

Hypertherm USA Manufactured (Plasma & Controller

Specialists)

Easy to Use Touch Screen Interface

Easy to Realize Perfect Cutting Parts with Low Operator

Training

Can Realize Parts via the CNC Controller with a DXF/DWG File

Updateable to High Definition Cutting, Bevel Cutting, Pipe Cutting

etc.

Windows 10 Interface for Long Life Support (Windows XP is no

longer supported by Windows)

Full Integration of Hypertherm Suite (Plasma, Controller &

Software)

Hypertherm Plasma Unit Benefits:

Hypertherm USA Manufactured (Plasma & Controller

Specialists)

Small & Lightweight Design with High Functionality

Cutting Up to 40mm Steel (Edge Start with PM125)

Smart Sense Technology to Ensure Air Pressure is Always Correctly

Set

A Wide Range of Consumables for Thin & Thick Cutting

Higher Cut Speeds for Production Cutting

Error Code Fault Finding for Easier Repairing

Safety Features Including Plasma Reset when Consumables Change

(Prevent Burning Hand)

Portability Can Allow You to Use the Plasma as Mechanized and

Handheld

Full Integration of Hypertherm Suite (Plasma, Controller &

Software)

Hypertherm PRONEST LTS CAM Software Benefits:

Hypertherm USA Designed and Written

Expert Cutting Techniques automatically achieved (Hypertherm

Plasma)

Auto Nesting Parts (Have multiple sheets of parts programmed in

less than 1 minute)

Very Easy to Use (Easy for beginners to use)

Full Integration of Hypertherm Suite (Plasma, Controller &

Software)

Our Advanced Auto Height Control Lifter Benefits:

Hypertherm Lifter Software

Auto Torch Height Control (Maintains Correct Cutting Height)

Arc Voltage Reading (Precision Accuracy to Improve Cut Quality)

Arc Voltage Sampling (Adjusts For Electrode Wear = Longer

Consumable Life)

EtherCAT Driven (Software Controlled Height Lifter

Special Cutting Techniques for Improved Hole Cutting

Important for Production Cutting

Full Integration of Hypertherm Suite (Plasma, Controller &

Software)

Digital Motor Benefits:

Industrial Consistency (Long Lasting)

Brushless Servos

Produces Less Noise & Vibration (Smooth Motion)

Higher Acceleration

High Speed & Torque Range

Real Positioning Feedback

High Repeatability

Fault Finding

EtherCAT Drive Benefits:

Future Upgradability

Faster Communication (Quick Response Times)

Multiple Applications (Multiple Tools)

Remote Feedback (Access Drive Information Remote Location)

High Precision

Low initial Cost

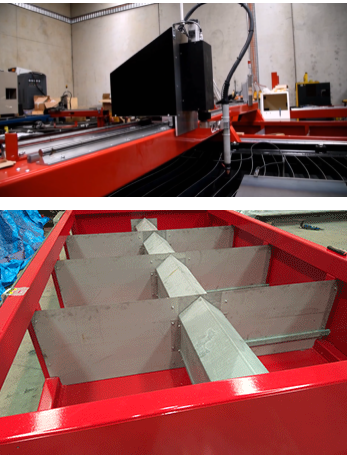

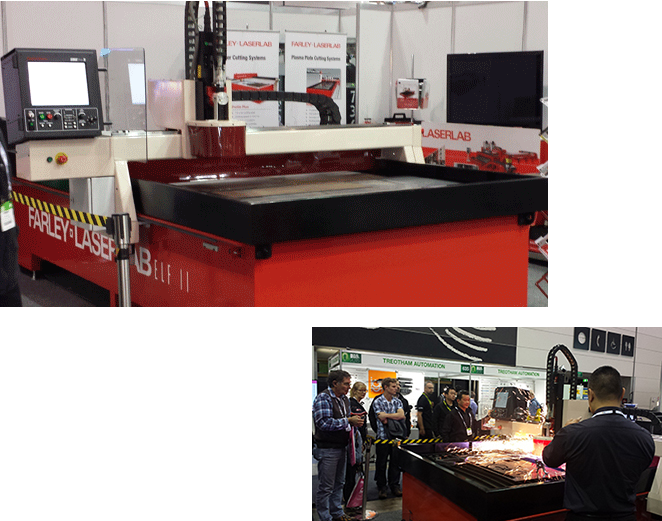

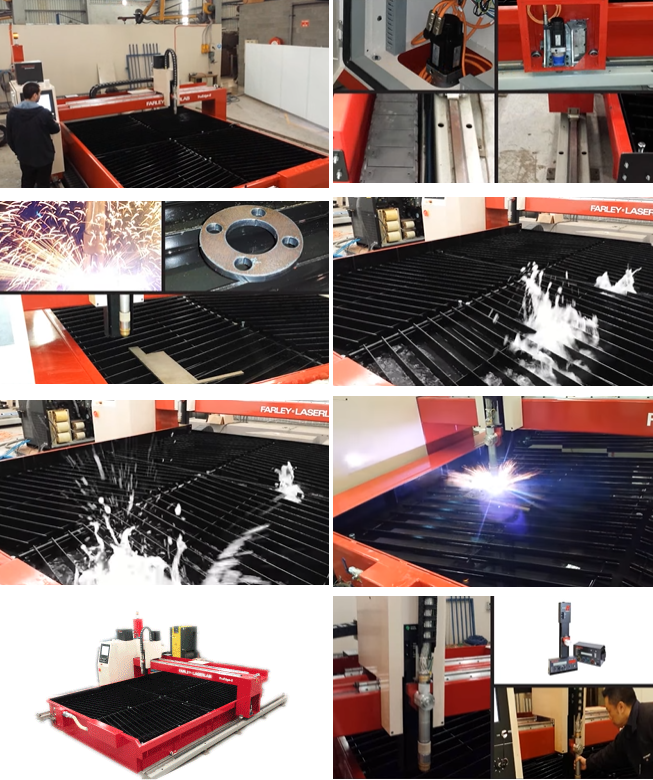

ELF 2 STD Plasma Machine

We are together upgrading an old favourite to the new generation of plasmas with the ELF 2. As many workshop will remember the original ELF 1 Plasma cutting machine being a staple in their factory for 10+ years with its heavy duty design and low pricing, it became one of our together most popular machine in our national markets and now we are bringing it back to be one of the most affordable heavy duty plasma cutting machines on the market today.

With a new design the ELF 2 is now a table machine, with its rails now mounted on the machine it provides you a more space friendly option for your workshop. The table mounted rails escape the issues of heat distortion through its unique design features and capped temperature control to insure your table lasts you longer than other machines. Coming in 2 options with the Hypertherm Max Pro Range and the Hypertherm High Definition Range.

ELF 2 STD ADVANTAGES

UPGRADEABLE - If you want to start off small with the Hypertherm PowerMax Plasma to grow your business then at a later date upgrade to a larger system all you need to do is change the Plasma and off you go. If you want to upgrade to the Hypertherm High Definition Plasma all you need to do is change the Plasma & Height Lifter and you are ready. Besides; you still can keep your smaller plasma cutter in your workshop to use as your handheld system, so you are not losing out on anything and not double paying for another table, controller and etc. when it is all there ready to go.

LONGER LASTING CONSUMABLES - With the Hypertherm Controller and Height Sensor it automatically changes the height of your torch to suite the amount of use of your plasma consumables which means you do not need to change them straight away. Unlike other systems which you will have to fiddle around with the controller to get the optimum torch height levels if it has the option at all. So; that means you will be saving a lot of money on your plasma consumables!

EASIER TO USE - With the Edge Connect Controller it makes plasma cutting easier than ever before with a large touch screen that directs you through a step by step cutting process utilizing Hypertherm's expert database of parameters which has been tested through 1000's of machines across the world. Take advantage of the easy to use controller and cutting system and save on time, money and troubles.

QUALITY CUTTING - Using our ELF 2 plasma machine it gives you a superior cut than through its quality engineered and built motion system that meets and exceeds Hypertherm standard of cutting. This will prevent any extra work such as dross removal and cleaning from materials that have simple designs. When quoting the same plasma torch the motion system provides a significant difference in the quality of cutting, so don't just look at the plasma torch, look at the machine as well and get some samples cut and you will see the difference.

HEAVY DUTY DESIGN – Our ELF 2 Plasma cutting machine is designed and built to hold and cut up to 60mm+ materials which gives you the reassurance that you can cut thick material like any quality job shop should provide. Make sure you check out the quality of the table as you might buy a Quality plasma but later realise you can not cut thick materials as the table will not hold it properly or cause heat distortion which will further ruin your motion system.

FULLY SUPPORTED – We together have a competent team of engineers and technicians to deal with any questions that you may face with your machine with full warranties to give you the peace of mind that you are getting a quality machine with quality support. Not only do you have our teams, you can utilize Hypertherm's support network with cutting parameters and technical questions to support their controller, height sensor,software and plasma source. This means you get two large companies that will always be around to support your machine.

TRUE HOLE CAPABLE - With upgrades to the ELF 2 High Definition plasma cutting machine you get all the benefits of Hypertherm's True Hole Cutting that will give you that extra edge in quality cutting which will help you win those extra jobs.

Here; We, Together Proudly Present Our Plasma Cutting, Drilling & Milling Machines Selection

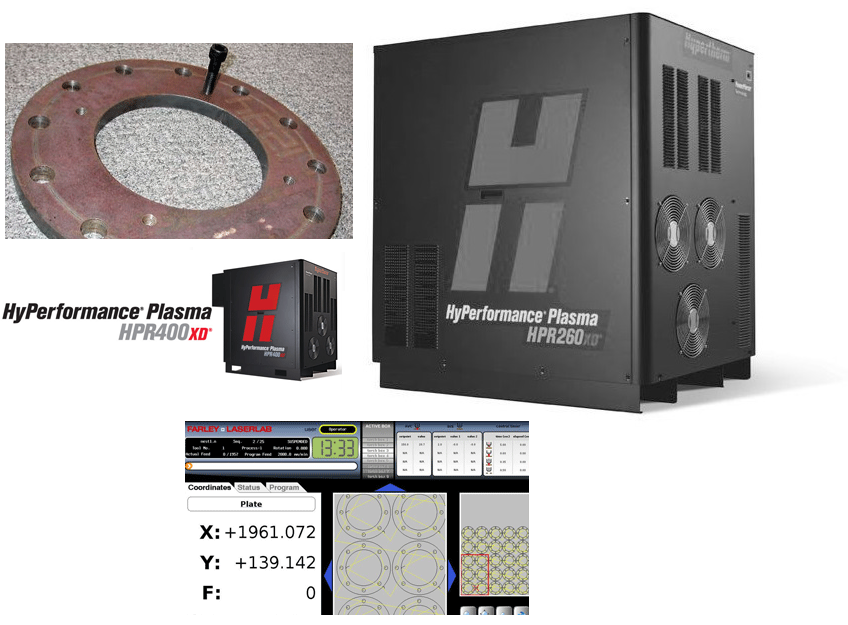

HIGH DEFINITION PLASMA CUTTING MACHINES:

ELF 2 XPR HD PLASMA CUTTING MACHINE

TRUEDGE 1 PLASMA CUTTING MACHINE

TRUEDGE 2 PLASMA CUTTING MACHINE

TRUEDGE 3 BEVEL PLASMA CUTTING MACHINE

Please proceed below for detailed information.

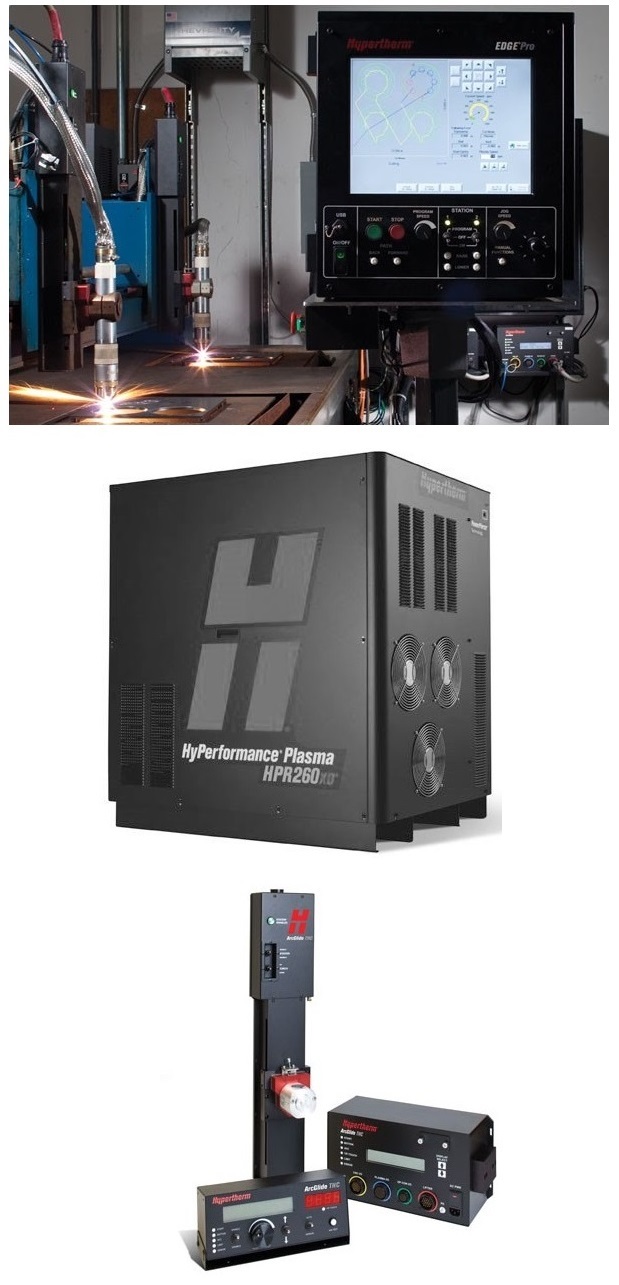

ELF 2 XPR HD Plasma Machine

The ELF 2 XPR HD Plasma Machine has been engineered to give you all the best quality Hypertherm Components to combine to give you the most affordable High Definition Plasma Cutting Machine on the Global Market today. Meaning you get the best quality Hypertherm Cut including the Hypertherm Patented "True Hole Technology" all at the best prices. So now for a very competitive price level you will be able to achieve the best quality plasma cutting on the market to be competing successfully against others who have spent more than double.

Coming with the patented Hypertherm HD SureCut Technology.

Therefore combining:

Hypertherm XPR 170 or 300 Plasma Source

Hypertherm Edge Connect CNC Controller

Hypertherm Sensor THC Lifter

Bosch Drives & Motors

Hypertherm Pronest CAM Software

ELF 2 XPR HD ADVANTAGES

LONGER LASTING CONSUMABLES - With the Hypertherm Controller and Height Sensor it automatically changes the height of your torch to suite the amount of use of your plasma consumables which means you do not need to change them straight away. Unlike other systems which you will have to fiddle around with the controller to get the optimum torch height levels if it has the option at all. So; that means you will be saving a lot of money on your plasma consumables!

EASIER TO USE - With the Edge Pro Ti Controller it makes plasma cutting easier than ever before with a large touch screen that directs you through a step by step cutting process utilizing Hypertherm's expert database of parameters which has been tested through 1000's of machines across the world. Take advantage of the easy to use controller and cutting system and save on time, money and troubles.

QUALITY CUTTING - Using our advanced ELF 2 plasma machine it gives you a superior cut, through its quality engineered and built motion system that meets and exceeds Hypertherm standard of cutting. This will prevent any extra work such as dross removal and cleaning from materials that have simple designs. When quoting the same plasma torch the motion system provides a significant difference in the quality of cutting, so don't just look at the plasma torch, look at the machine as well and get some samples cut and you will see the difference.

HEAVY DUTY DESIGN – The ELF 2 Plasma cutting machine is designed and built to hold and cut up to 60mm+ materials which gives you the reassurance that you can cut thick material like any quality job shop should provide. Make sure you check out the quality of the table as you might buy a Quality plasma but later realise you can not cut thick materials as the table will not hold it properly or cause heat distortion which will further ruin your motion system.

FULLY SUPPORTED – We have a competent team of engineers and technicians to deal with any questions that you may face with your machine with full warranties to give you the peace of mind that you are getting a quality machine with quality support. Not only do you have our teams, you can utilize Hypertherm's support network with cutting parameters and technical questions to support their controller, height sensor,software and plasma source. This means you get two large companies that will always be around to support your machine.

TRUE HOLE CAPABLE - With upgrades to the ELF 2 High Definition plasma cutting machine you get all the benefits of Hypertherm's True Hole Cutting that will give you that extra edge in quality cutting which will help you win those extra jobs.

Automatic Gas Console

TruEdge 1 Plasma Machine

The TruEdge-I plasma cutting machine provides high quality small holes with reduced taper, reduces cost per part and improved cut quality at an attractive entry level price. The TruEdge machine is a great plasma cutting solution for companies that have little to no plasma experience, because of the high level of integrated plasma cutting technology.

This technology is very easy to use and can have any operator with minimal to no plasma cutting experience producing cut parts better than the most seasoned and experienced professional. The new range of our TruEdge machine incorporates all the latest Hypertherm plasma cutting technology including True Hole technology. The TruEdge is a quality built motion system equipped with digital SERCOS Bosch motors and drives.

TruEdge 2 Plasma Cutting Machine

The TruEdge-II machine delivers high quality small holes with excellent cut quality and high performance. The machine come standard with a dross box fume extraction table that allows you to remove the the dross box and replace with a spare to reduce machine down time.

The TruEdge-II is based on the very popular Magician Plasma Machine and is a High Performance, High Quality motion system. *Coming with NEXT Generation Hypertherm Edge Connect Controller and Bosch EtherCAT Drives. This will become very important for future upgrades from Hypertherm's Cutting Technology.

TruEdge 3 Bevel Plasma Cutting Machine

The TruEdge 3 machine delivers high quality small holes with excellent cut quality and high performance. The machine come standard with a dross box fume extraction table that allows you to remove the the dross box and replace with a spare to reduce machine down time. The TruEdge 3 is based on the very popular Trident Plasma and is a High Performance, High Quality motion system.

Designed to be utilized with the Hypertherm True Bevel Technology giving you an easy to use bevel cutting that can produce "Y" and "V" Bevel cuts at ease. Coming with NEXT Generation Hypertherm Edge Connect Controller and Bosch EtherCAT Drives. This will become very important for future upgrades from Hypertherm's Cutting Technology.

The TruEdge Advantage:

Easier to operate

Consistently cut excellent quality holes

Extend consumable life

Remote diagnostics

Integrated CAM software

Choice of high definition plasma systems

Long life reliable motion system

TruEdge 3 Machine Options

Bevel Cutting Head (Y and A Bevels)

Single Drill Head (up to 25mm Diameter)

CHS & RHS Pipe Cutting Rotary Axis (up to 300mm)

Multiple Plasma & Oxy Cutting Torches

Here; We, Together Proudly Present Our Plasma Cutting, Drilling & Milling Machines Selection

HEAVY DUTY PLASMA CUTTING MACHINES WITH DRILLING OPTION:

MAGICIAN PLASMA CUTTING MACHINE

TRIDENT PLASMA CUTTING MACHINE

Please proceed below for detailed information.

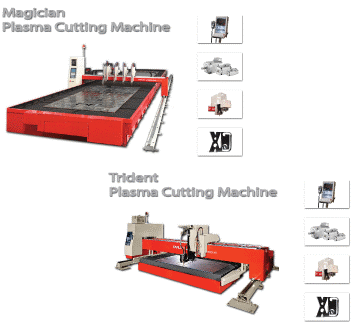

Magician Plasma & Drilling Machine

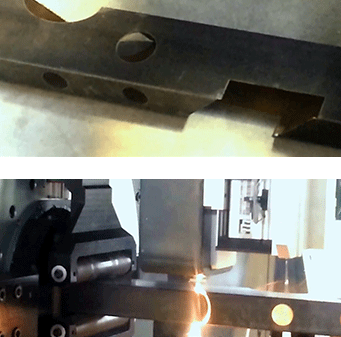

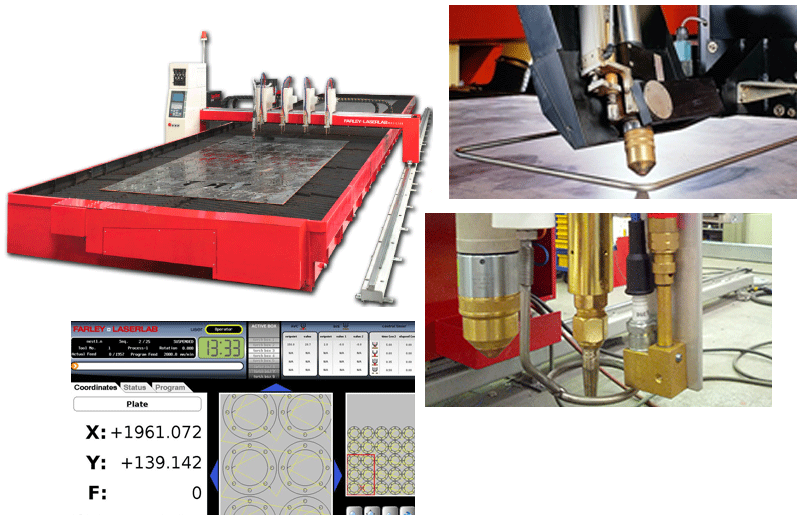

The Magician is a small footprint multi-torch cutting machine designed to deliver precision, high definition plasma cutting, oxy-fuel cutting and drilling. The Magician is one of the thoroughbreds of our stable machine ions and achieves its accuracy and high productivity by utilising single piece fabricated beam construction, which eliminates all bolted joints.

Combined with twin side-drives through high precision planetary gearboxes, the result is a machine light enough to achieve plasma profiling speeds of up to 20m/min yet retaining the rigidity to accept up to 6 torches for multi-torch plate cutting of 150mm thick material, and also a drilling head with eight BT 30 tools.

Low rails for rigidity & higher productivity

The low level rail construction improves accuracy and stability

while reducing the chances of damage from swinging loads on cranes

and forklifts.

Low rails improve operator access, speeding up loading and

unloading and reducing potential safety problems.

Combination drives for greater accuracy

AC servo drives and planetary gearboxes provide the torque and

resolution necessary to ensure accurate position through the life

of the machine.

The drive system ensures high stiffness essential for accuracy,

minimal backlash and easy adjustment.

Optimum acceleration is ensured through the use of Siemens AC

motors.

Twin drive system ensures torch accuracy.

New BT30 Drill Head

BT30 tool holder, accommodating 8 tools.

Drilling capacity 25mm.

Torch carriage versatility

The rack & pinion primary torch carriage can be fitted with up

to three lifters, to accommodate the plasma torch, oxy-fuel torch,

marker and centre drill.

Up to three additional slave torch carriages can be fitted. These

are driven by the primary torch carriage by a stainless steel band

and can be configured for various tools.

Our Advanced PDF TS control

The PDF TS 32-bit CNC system with user-friendly interface &

large 17” TFT touch screen for control, accuracy &

diagnostics.

Our Advanced BT30 Drill Head

Trident Plasma & Drilling Machine

The Trident is a large footprint multi-torch cutting machine designed to deliver precision, high definition plasma cutting, oxy-fuel cutting and drilling. The Trident is ideally suited to high volume cutting environments such as shipyards, steel services & distribution centres and shops that require continuous operation – 3 shifts per day, year after year.

The Trident is one of the thoroughbreds of our stable machine ions and achieves its accuracy and high productivity by utilising single piece fabricated beam construction, which eliminates bolted joints. Combined with twin side-drives through high precision planetary gear boxes, the result is a machine light enough to achieve plasma profiling speeds of 20m/min yet retaining the rigidity to accept up to 6 torches for multi-torch plate cutting of 250mm thick material. The Trident also has a drilling head with eight BT 40 tools, with the capacity to drill 32mm diameter holes.

Low rails for rigidity & higher productivity

The low level rail construction improves accuracy and stability

while reducing the chances of damage from swinging loads on cranes

and forklifts.

Low rails improve operator access, speeding up loading and

unloading and reducing potential safety problems.

Combination drives for greater accuracy

AC servo drives and planetary gearboxes provide the torque and

resolution necessary to ensure accurate position through the life

of the machine.

The drive system ensures high stiffness essential for accuracy,

minimal backlash and easy adjustment.

Optimum acceleration is ensured through the use of Siemens AC

motors.

Twin drive system ensures torch accuracy.

New BT40 Drill Head

BT40 tool holder, accommodating 8 tools.

Drilling capacity 32mm.

Torch carriage versatility

The rack & pinion primary torch carriage can be fitted with up

to three lifters, to accommodate the plasma torch, oxy-fuel torch,

marker and centre drill.

Up to three additional slave torch carriages can be fitted. These

are driven by the primary torch carriage by a stainless steel band

and can be configured for various tools.

Our Advanced PDF TS control

The PDF TS 32-bit CNC system with user-friendly interface & large 17” TFT touch screen for control, accuracy & diagnostics.

Our Advanced BT40 Drill Head

Here; We, Together Proudly Present Our Plasma Cutting, Drilling & Milling Machines Selection

HEAVY DUTY PLASMA CUTTING & DRILLING MACHINES:

HERCULES PLASMA CUTTING & DRILLING MACHINE

Please proceed below for detailed information.

Hercules Plasma & Drilling Machine

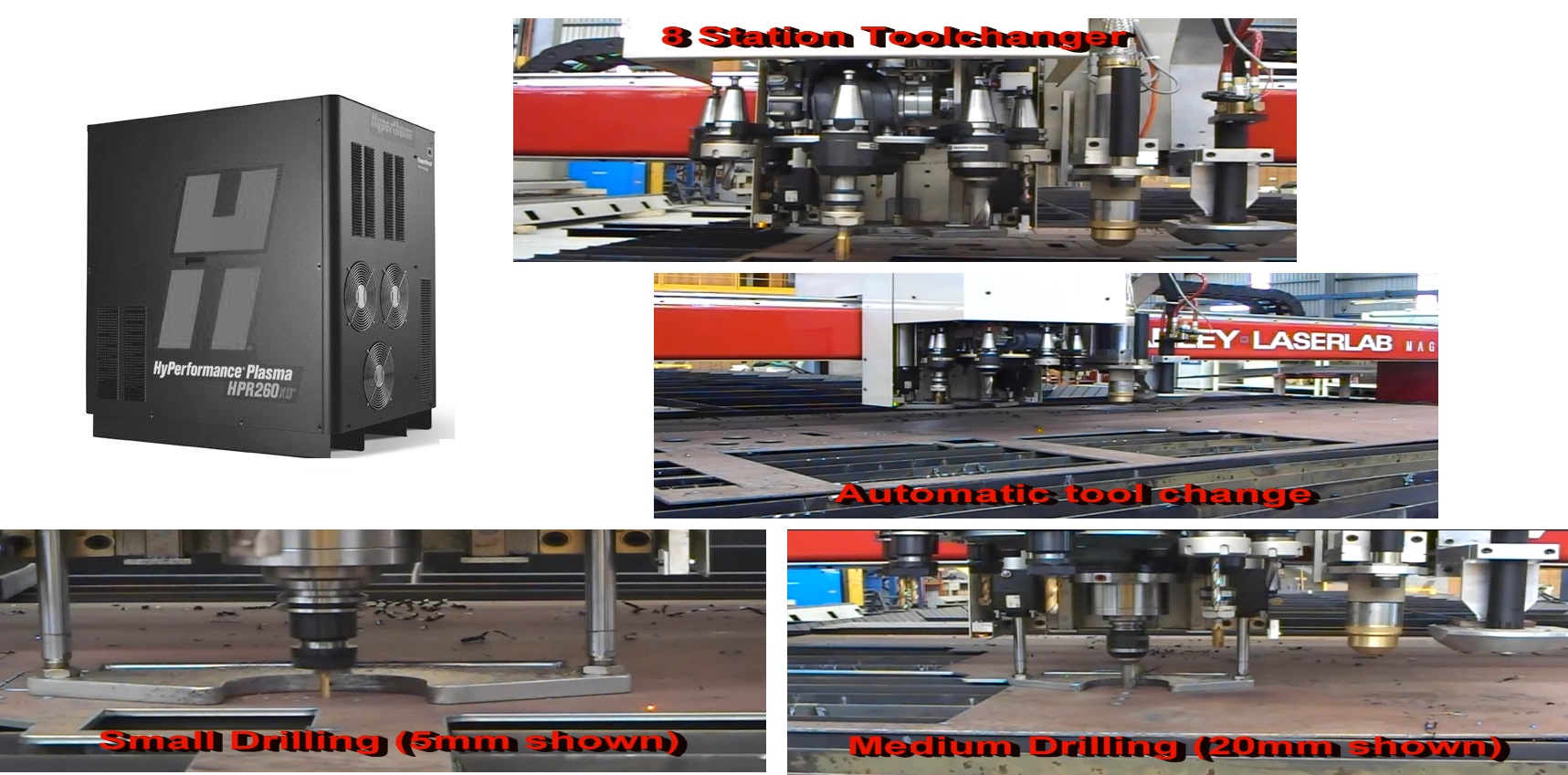

COMBINED PLASMA CUTTING AND DRILLING MACHINE FOR MULTI PROCESS MANUFACTURING

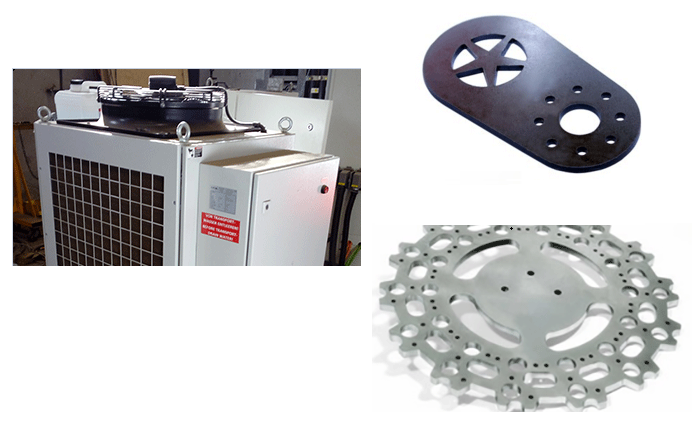

Precision plasma and oxy-fuel cutting, marking, drilling and tapping to high tolerances, in one set-up. This machine is ideal for multi-processing production parts that require medium sized drilling. The Hercules has provided job shops to OEMs with the competitive edge.

Taking a total systems approach, it has been designed and manufactured the latest in plate processing systems, combining plate marking, drilling, tapping and cutting all in one unique set-up.

600 HOLES PER HOUR

This is the benchmark for our Hercules 600 holes, 20mm (3/4”) diameter in 20mm (3/4”) plate at 100mm (4”) centres.

In the fabrication, construction, building, boiler and other value added industries, hole drilling is often an undervalued function, and possessing a machine that can drill effectively and reliably will enhance your ability to remain competitive.

The Hercules is both quick and accurate at drilling and can also chamfer, counterbore, bore and tap holes.

The Hercules uses the latest in drill tooling technology to ensure our customers are always in front.

VERSATILITY PLUS!

The combined drilling and cutting process drastically reduces materials handling, work in progress and eliminates costly bottlenecks.

The versatility, functionality and speed of the Hercules is suited to almost any fabrication environment, whether it be yellowgoods, machinery manufacturing, steel construction or bridge building. Give us your requirements:

• Plate size

• Typical plate thickness

• Typical part drawing

• Type of downstream operations

Let us show you how to increase productivity in your plant.

COMBINING OPERATIONS CUTS WORK-IN-PROGRESS

Combining marking, drilling, tapping and cutting operations onto one machine has an immediate effect on work-in-progress.

• Eliminate double handling

• JIT and KANBAN capable system

• Kit of parts capability

• Design flexibility for product development and tailoring

• Better utilisation of resources

• Less floor space

• Load and unload without stopping

REDUCED MATERIALS USAGE

The capacity to process wider and longer plate will produce savings in both material and time.

SLASHED LEAD TIMES

Combining easy programming, quick set-ups, multi-tooling with high machine performance gives Hercules customers the leading edge in very competitive markets.

TOOLING FLEXIBILITY

The Hercules utilises a fully programmable “through coolant” spindle, achieving speeds between 100 and 4500 rpm, ensuring that the modern carbide drills can be used to their optimum. With up to 20 plus different tools, the Hercules can tap, bore, counter-sink and even perform back chamfering.

Plasma Bevel Head

Here; We, Together Proudly Present Our Plasma Cutting, Drilling & Milling Machines Selection

HEAVY DUTY PLASMA CUTTING, DRILLING & MILLING MACHINES:

FABRICATOR XRP PLASMA CUTTING, DRILLING & MILLING MACHINE

Please proceed below for detailed information.

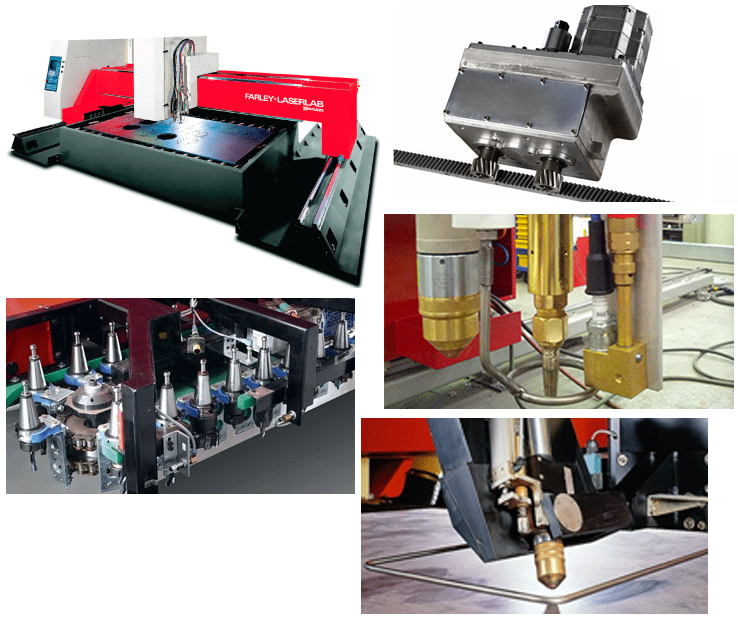

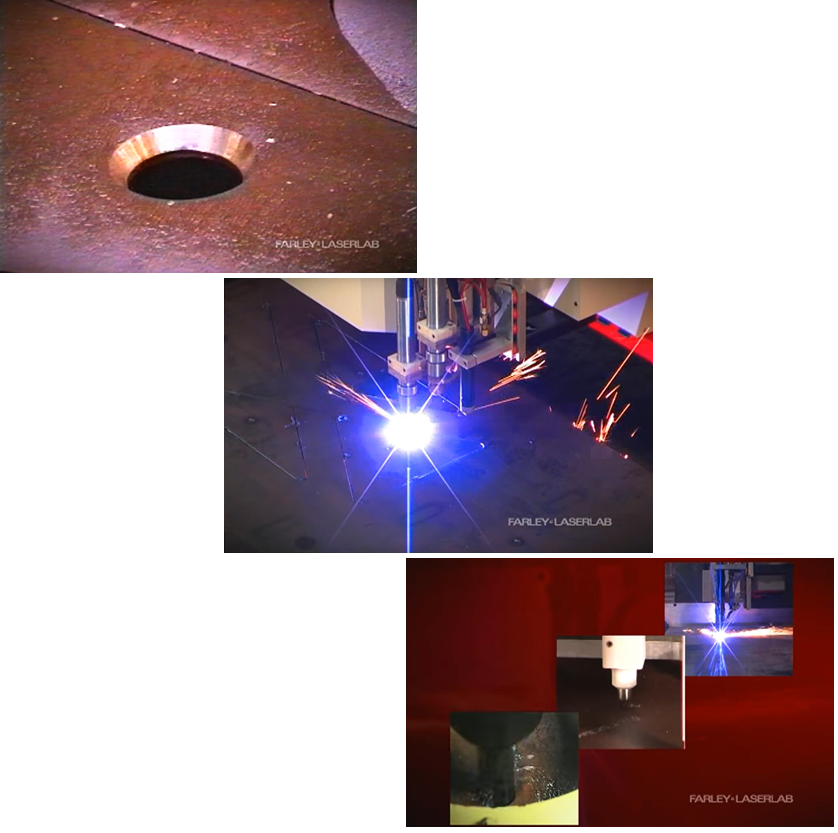

Fabricator XRP Plasma, Drilling & Milling Machine

COMPLETE PLATE PROCESSING MACHINE WITH PLASMA CUTTING, HIGH SPEED DRILLING AND MILLING

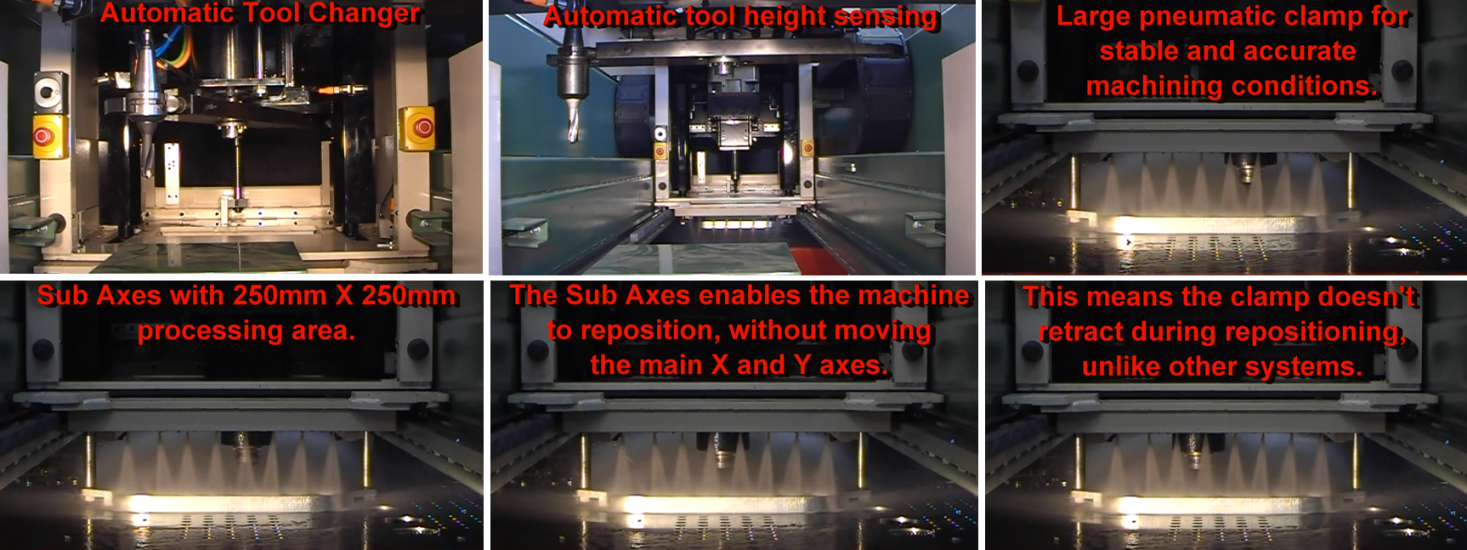

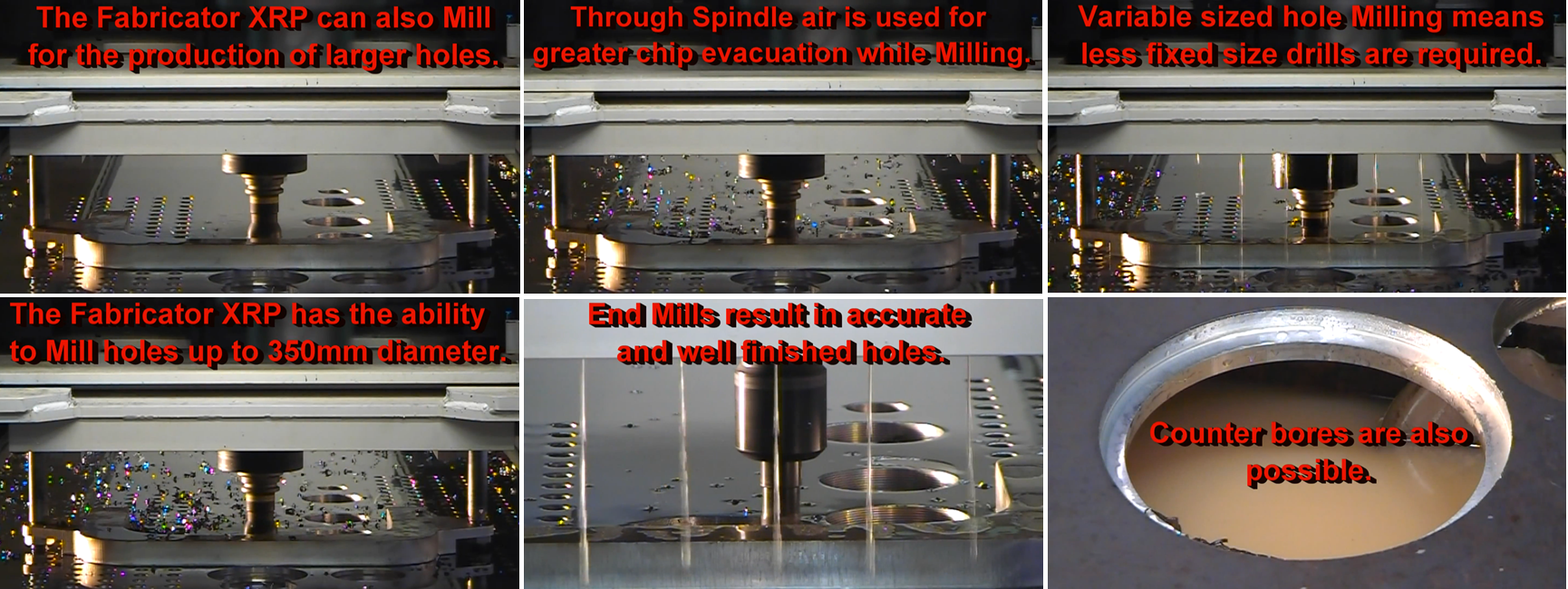

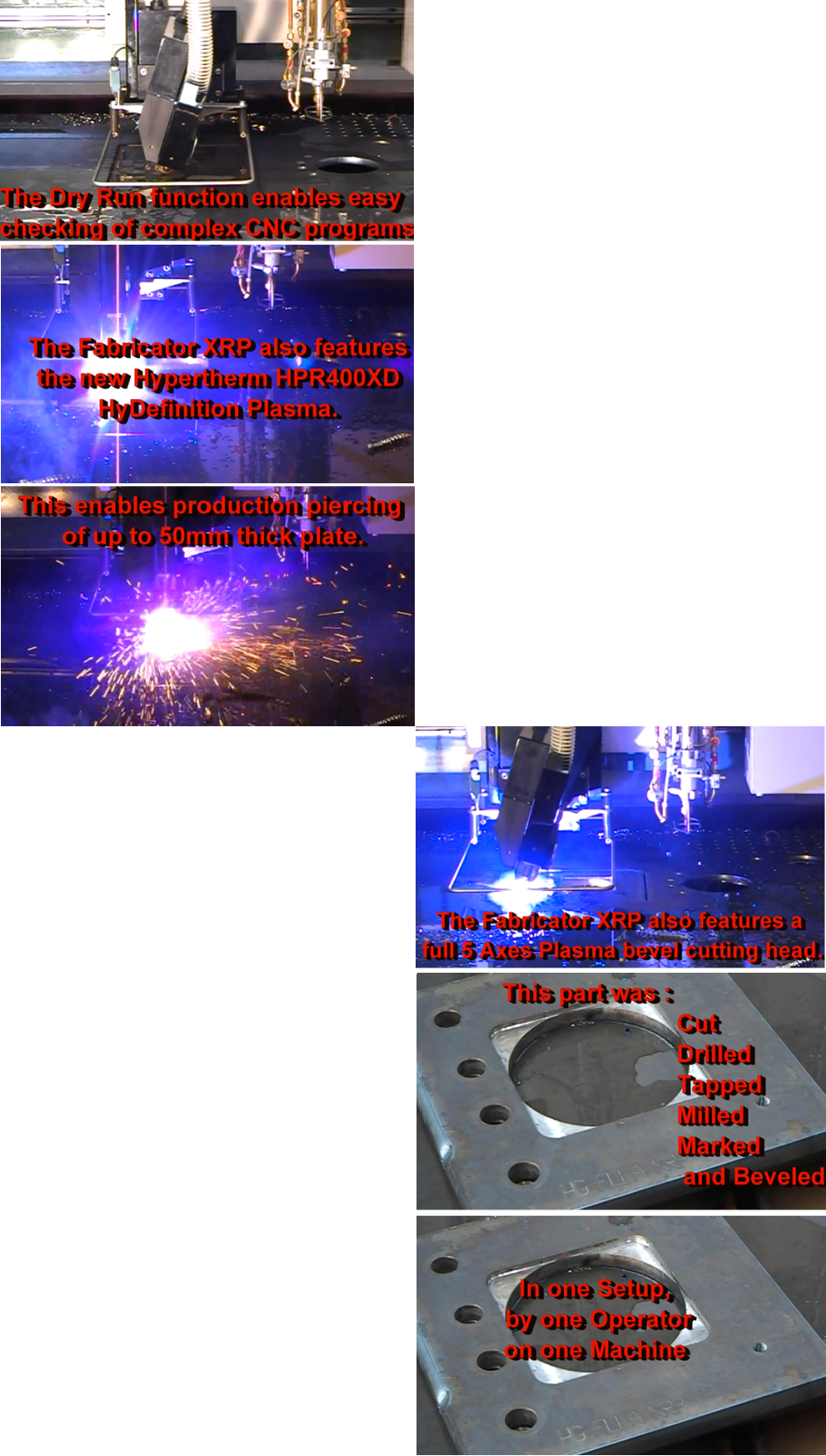

The Fabricator XRP is a next generation complete plate processing system combining the very best cutting, marking, drilling and milling technologies. The innovative sub-axes drilling capability provides the drillhead with a range of movement independent of the main machine X & Y axes, creating a 250mm x 250mm clamped work envelope for continuous, uninterrupted machining.

The XRP is currently operational in Australia and the U.S.A. producing complex parts, to finished quality, straight off the table, in one set-up, with one operator.

This flexible, user-friendly, duel beam, multi-carriage, multi-torch machine is for the big industry players looking for a fully automated and integrated system that eliminates downtime between processes, is simple enough for one operator to setup and run and provides an impressive return on investment.

While achieving the very best cutting performance from Hypertherm's new HPR400XD HyDefinition plasma systems (capable of piercing 50mm MS), it is the innovative sub-axes drilling capability that sets a new industry standard. Watch the video to see the Fabricator XRP sub-axes in action both drilling and milling.

Components: Hypertherm HyDefinition plasma up to 400 amp, 5-axis bevel head, oxy-fuel systems, marking systems, BT40 spindle taper with 40 tool changer, raise/lower water table and touch screen controller. All Siemens servos and drives.

Plasma Bevel Head

MATRIX OF OUR PLASMA CUTTING, DRILLING & MILLING MACHINES

|

Machine Options |

EcoShape Machine |

QuikEDGE Machine |

ELF 2 Machine |

TruEDGE Machine |

Trident Machine |

Fabricator Machine |

|

|

PowerMax |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

Plasma Unit |

|||||||

|

MaxPro 200 |

x |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

Plasma Unit |

|||||||

|

HPR130 & XPR300 Plasma Unit |

x |

x |

Yes |

Yes |

Yes |

Yes |

|

|

HPR400 & HPR800 Plasma Unit |

x |

x |

x |

Yes |

Yes |

Yes |

|

|

Oxy Cutting (40mm plate) |

Yes |

Yes |

Yes |

x |

x |

x |

|

|

Oxy Cutting (150mm plate) |

x |

x |

x |

Yes |

Yes |

Yes |

|

|

Auto Bevel Cutting |

x |

x |

x |

Yes |

Yes |

Yes |

|

|

CHS Pipe Cutting |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

SHS & RHS Cutting |

x |

x |

x |

Yes |

x |

x |

|

|

Spot Drilling (up to 12mm) |

Yes |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

8 Auto Tool changer Drill (up to 32mm) |

x |

x |

x |

x |

Yes |

Yes |

|

|

Milling |

x |

x |

x |

x |

x |

Yes |

|

|

Air Scribe Marking |

x |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

Hypertherm SureCut Technology |

x |

x |

Yes |

Yes |

x |

x |

|

|

Consumable Long Life |

x |

Yes |

Yes |

Yes |

Yes |

Yes |

|

|

Multiple Plasma Torches |

x |

Yes |

Yes |

Yes |

Yes |

Yes |

Here; We, Together Proudly Present Our WaterJet Cutting Machines Selection

QuiKEDGE WATERJET MACHINE

ELF 2 JET - WATERJET MACHINE

MAGICIAN JET - WATERJET MACHINE

Please proceed below for detailed information.

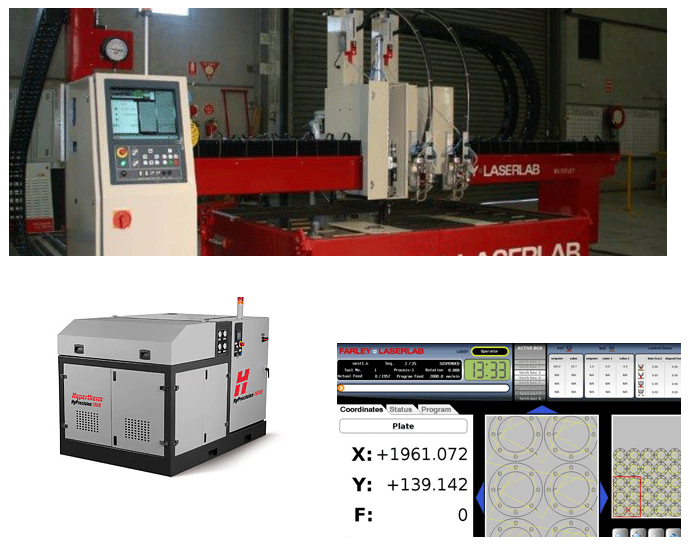

QuikEDGE WaterJet Cutting Machine

The QuikEDGE Waterjet Machine combining the lastest in Hypertherm USA Technology with heavy build is a success story. This QuikEDGE Machine is ideal for the HVAC Market cutting insulation fiber glase and rubber materials. Taking over the hand cutting method and CNC knife systems that has issues with breaking and a hazourdous workshop.

The QuikEDGE WaterJET comes with the following options;

Therefore combining:

QuikEDGE Machine

Hypertherm HyPrecision Waterjet Source

Hypertherm Edge Connect CNC Controller

Bosch Drives, Motors & Planetary Geaboxes

Hypertherm Pronest LT CAM Software

Lower your cost with increased reliability

Hypertherm HyPrecision waterjets were engineered using Advanced Intensifier Technology (AIT). By rethinking the way the intensifier pump works, we were able to make it work harder, last longer and require less service time. AIT, it’s what makes Hypertherm HyPrecision waterjets more cost effective than any other waterjet in the world.

Easier servicing

Hydraulic rod seals and plunger bearings are readily accessed from the outside of the hydraulic end cap.

Longer lasting

Hydraulic center section features an advanced piston design, which minimizes seal wear and improves component life.

Streamlined Access

Check valve utilizes a screwless, low-pressure poppet design that enables quick evaluation of key contact surfaces. This feature also allows for noticeably faster component replacement.

Optimized shifting

Advanced electronics provide smooth, reliable shifting for optimum cut quality. Shift times are even monitored to ensure optimal pump performance.

Simpler high-pressure ends

Durable threaded-rod design simplifies high-pressure end removal for quick seal maintenance. Meanwhile, the nonthreaded cylinder design increases reliability.

Prolonged seal life

Large diameter ceramic plunger produces more water per stroke with reduced friction, yielding maximum seal life.

ELF 2 WaterJet Cutting Machine

The ELF 2 WaterJet Machine has been engineered to give you all the best quality Hypertherm Components to combine to give you the most affordable High Quality WaterJet Cutting Machine on the Global Market today. Meaning you get the best quality Hypertherm Cut including all at the best prices.

So; now at a very competitive price level you will be able to achieve the best quality, consistent and easy to use low maintenance WaterJet cutting on the market to be compete against others who have spent almost double of it.

The ELF 2 WaterJet comes with the following options;

Therefore combining:

Hypertherm HyPrecision Waterjet Source

Hypertherm Edge Pro Ti CNC Controller

Hypertherm Drives & Motors

Hypertherm Pronest CAM Software

Lower your cost with increased reliability

Hypertherm HyPrecision waterjets were engineered using Advanced Intensifier Technology (AIT). By rethinking the way the intensifier pump works, we were able to make it work harder, last longer and require less service time. AIT, it’s what makes Hypertherm HyPrecision waterjets more cost effective than any other waterjet in the world.

Easier servicing

Hydraulic rod seals and plunger bearings are readily accessed from the outside of the hydraulic end cap.

Longer lasting

Hydraulic center section features an advanced piston design, which minimizes seal wear and improves component life.

Streamlined Access

Check valve utilizes a screwless, low-pressure poppet design that enables quick evaluation of key contact surfaces. This feature also allows for noticeably faster component replacement.

Optimized shifting

Advanced electronics provide smooth, reliable shifting for optimum cut quality. Shift times are even monitored to ensure optimal pump performance.

Simpler high-pressure ends

Durable threaded-rod design simplifies high-pressure end removal for quick seal maintenance. Meanwhile, the nonthreaded cylinder design increases reliability.

Prolonged seal life

Large diameter ceramic plunger produces more water per stroke with reduced friction, yielding maximum seal life.

Magician WaterJet Cutting Machine

The Magician WaterJet Machine has been engineered to give you all the best quality Hypertherm Components to combine to give you the most affordable High Quality WaterJet Cutting Machine on the Global Market Today. Meaning you get the best quality Hypertherm Cut including all at the best prices.

So; now at a very competitive price level you will be able to achieve the best quality, consistent and easy to use low maintenance WaterJet cutting on the market to be compete against others who have spent almost double of it.

The Magician WaterJet comes with the following options

Therefore combining:

Hypertherm HyPrecision Waterjet Source

Our Advanced PDF TS CNC Controller

Siemens Drives & Motors

Hypertherm Pronest CAM Software

Lower your cost with increased reliability

Hypertherm HyPrecision waterjets were engineered using Advanced Intensifier Technology (AIT). By rethinking the way the intensifier pump works, we were able to make it work harder, last longer and require less service time. AIT, it’s what makes Hypertherm HyPrecision waterjets more cost effective than any other waterjet in the world.

Easier servicing

Hydraulic rod seals and plunger bearings are readily accessed from the outside of the hydraulic end cap.

Longer lasting

Hydraulic center section features an advanced piston design, which minimizes seal wear and improves component life.

Streamlined Access

Check valve utilizes a screwless, low-pressure poppet design that enables quick evaluation of key contact surfaces. This feature also allows for noticeably faster component replacement.

Optimized shifting

Advanced electronics provide smooth, reliable shifting for optimum cut quality. Shift times are even monitored to ensure optimal pump performance.

Simpler high-pressure ends

Durable threaded-rod design simplifies high-pressure end removal for quick seal maintenance. Meanwhile, the nonthreaded cylinder design increases reliability.

Prolonged seal life

Large diameter ceramic plunger produces more water per stroke with reduced friction, yielding maximum seal life.

Here; We, Together Proudly Present Our Laser Marking & Laser Welding Machines Selection

LASER MARKING MACHINES:

FIBER LASER MARKING MACHINE

CO2 LASER MARKING MACHINE

CO2 FLYING LASER MARKING MACHINE

UV LASER MARKING MACHINE

3D LASER MARKING MACHINE

Please proceed below for detailed information.

Fiber Laser Marking Machine

The Fiber laser marking machine with CE standard has compact, portable structure and no optic-pollution, little energy coupling loss, air cooling concept, so it has exclusive advantages against other competitors. The less-power consumption with just 0.5 KW/Hour, long running life and maintenance-free for 100,000 hours are typical characters.

The laser beam quality is perfect for high-precision marking application. With professional software, it has strong functions and it can be operated in 24 hours and severe environment. It meets European market standards and satisfies high protection demands.

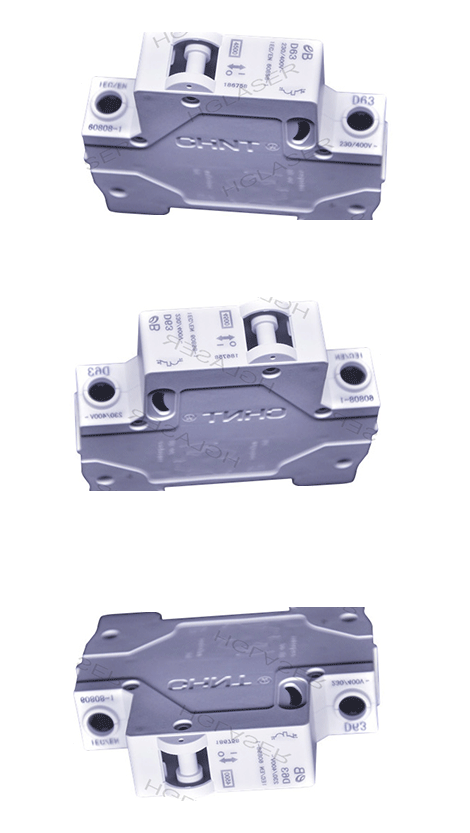

CO2 Laser Marking Machine

It is widely used in clothing accessories, leather, food beverage packaging, electronic components, crafts processing, glass stone processing, and other areas graphics and text marking and cutting. It is also used in many non-metallic materials marking, such as paper packaging, plastic products, labels, leather fabrics, glass ceramic, resin plastics, wood products, PCB boards, etc.

The desktop CO2 laser marking machine integrates advanced galvanometer laser marking technology with imported RF excited sealed CO2 laser.

According to human body engineering mechanics, the desktop design improves work efficiency of operators;

With high-speed galvanometer, the marking speed is 30% faster than similar products;

Long life, operated in 24 hours, long maintenance-free;

Powerful marking software, humanized operation interface, easy to be operated, without bothering for the operators altering;

Customize special machines according to customer requirements.

CO2 Flying Laser Marking Machine

Online laser marking system series integrate advanced galvanometer laser marking technology with imported RF excited sealed CO2 laser. Combining laser technology with production line, it can mark on rapid moving products.

This marking machine is mainly used in marking Chinese characters, English characters, figures, batch numbers, production dates, LOGO, real time clock information and anti-counterfeiting, especially the pharmaceutical industries GMP and food industries HACCP.

Flexible structure, fast speed, high security;

High efficiency, high electro-optic conversion efficiency;

Long life, easy operation, low running cost, operated in 24 hours.

It’s suitable for all kinds of nonmetals and some metals, such as paper, PVC, rubber, wood, glass, ceramic, plastic, PET, HDPE, leather, etc. And it is widely used in packing boxes, packaging bags, films, food cans, glass bottles, drink bottles, HDPE bottles, cables, pipes and electronic components industries.

Marking Font Scribing, dot matrix

UV Laser Marking Machine

Adopted with superior green and UV laser, the material is more easily absorbed and the thermal diffusion of material can be reduced. The method of breaking molecular bonds could make pure black, no-touch and more clearly printing effect marking.

The equipment is mainly used to mark Chinese characters, English, numbers, batch numbers, production dates, period of validity, LOGO, real time clock information and digital anti-counterfeiting, which meets the demand of pharmaceutical industry GMP and food industry HACCP.

Flexible structure, the professional stand can be installed on the assembly line, easy adjustment;

Professional industrial laser source, faster marking speed and consistent marking, high reliability, operated continuously in 24 hours, meet the demands of mass processing and production;

High electro-optic conversion efficiency, low consumption, long

life, save a lot of processing costs for customers;

Friendly man-machine dialogue interface, easy operation, without

bothering for the operators altering.

It is widely used in electronic components, integrated circuits, hardware, automobile parts, plastics, precision equipments and many other fields.

3D Laser Marking Machine

With the first-class marking technology, it can work on sculptured surface without defocus. Configured with specialized 3D vibrating mirror, the 3D dynamic laser marking can control the software and hardware, and the laser beam can mark on arbitrary 3D sculptured surface.

High precision of 3D positioning technology, high-speed focusing and scanning system, short pulse, high-peak power and HPRF (High Pulse Repetition Frequency);

With friendly operation interface, it is suit for many file formats, such as dxf, plt, cnc, step, iges, etc;

High electro-optic conversion efficiency, long life and easy maintenance;

Fast marking speed and high processing efficiency.

It’s suitable for all kinds of metals and nonmetals laser marking on 3D surface. It’s widely used in mobile manufacture, cubic circuits, medical equipments, moulds, 3C electronics, auto parts, electronic communication, etc.

Pulse Repeatable Frequency 10kHz - 200kHz

Mainframe 1200 x 1000 x 1610mm

Mainframe 350kg

Here; We, Together Proudly Present Our Laser Marking & Laser Welding Machines Selection

LASER WELDING MACHINES

SPOT WELDING LASER MACHINE

Please proceed below for detailed information.

Laser Spot Welding Machine

Spot laser welding machine is mainly used for jewelries reperforating, spot welding, mending and so on. It is suitable for gold, silver, platinum, stainless steel, titanium and the alloys. It can also be used in battery nickel straps, integrated circuit wires, kinescopes and electron-gun assemblies welding.

Adopted with imported ceramic in the core components, it has stable performance, long life, and offers an efficient and economic processing solution for customers;

With fast welding speed, it improves welding efficiency significantly and shortens the single workpiece welding time;

With high quality welding, beautiful welding seam, it greatly improves the passing rate of finished products without secondary processing;

Can work on refractory materials, especially miniature parts and jewelries;

Customize special machines according to customer requirements.

It is widely used in aviation, aerospace, sports goods, jewelries, medical treatment, instrumentations, mechanical mould processing, automobile and other fields. It is especially suitable for jewelry welding, mould repairing, golf ball repairing, spot welding for components, battery welding etc.

We would like to inform you regarding possible machine upgrades that we can provide for your all needs of various laser machine upgrades, plasma machine upgrades, waterjet machine upgrades and cam software upgrades.

Laser Machine Upgrades

Plasma Machine Upgrades

WaterJet Machine Upgrades

CAM Software Upgrades

Please contact us without hesitation for your all needs.

We would like to inform you regarding possible consumables & spare parts ion that we can provide for your all needs at various laser machines, plasma machines and waterjet machines.

We together hold over $500,000+ worth of spare parts & consumables to help keep our customers running everyday and if we do not have it in stock we have a good relationship with all our suppliers to get something in as quick as possible to keep you running smoothly.

Please contact us without hesitation for your all needs.

Spare Parts:

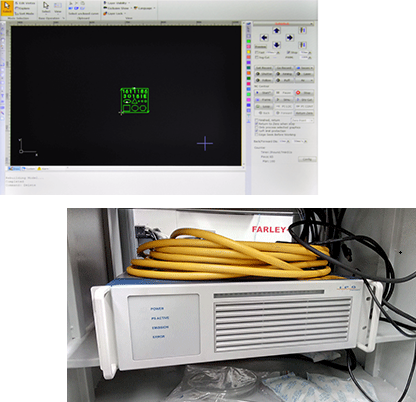

Farley Plasma Cutting Machines

- Siemens Spare Parts

- Bosch Spare Parts

- Hypertherm Spare Parts

Farley Laser Cutting Machines

- Rofin Spare Parts

- IPG Spare Parts

- Precitec Spare Parts

- Raytools Spare Parts

- Siemens Spare Parts

- Beckhoff Spare Parts

Consumables:

- Hypertherm Genuine Plasma Consumables

- Hypertherm Centricut Laser Consumables

- Precitec Cutting Consumables

- Raytools Cutting Consumables

- IPG & Rofin Cutting Lens & Filters

+ Many More

To get more detailed information about our products and service in this industry and regarding your all questions and quotation requests, please contact with us now!

Cookies are used on this site to improve the user experience and to make the site work more efficiently. For more information, please read our Cookie Policy.